Published On Feb 26, 2018

Antikythera Fragment #6 - Ancient Tool Technology - Making A Hand Powered Drill

The precision of the holes in the Antikythera mechanism is one of the most fascinating aspects of its construction. In this video I make a tool that is capable of creating holes to the required standard, yet is consistent with the level of technology known to have existed in the period.

The video where I show the drill bit making process in detail can be found here: • Antikythera Fragment #5 - Ancient Too...

The plans for this project, and a IGES file of the flywheel casting pattern can be downloaded as a zip file here (11mb): http://www.clickspringprojects.com/up...

If you would like to help support the creation of these videos, then head on over to the Clickspring Patreon page: / clickspring

________________________________________________________

A very special thank you to Patrons:

Sinking Valley Woodworks (http://www.sinkingvalleywoodworks.com)

Glenn Trewitt

Christopher Warnock

Mike Manfrin

Steven Sladewski

Rollin W. Patrick, Jr.

Jim Popwell

Gary Levario

Pete Askew

Norman Lemke

Andre van Soest

Andrew Smith

Bernd Fischer

Rudolph Bescherer Jr

Sam Towne

Adam Slagle

Jack Cause

Jeremiah G. Mort

Dave Seff

Olof Haggren

Stassinopoulos Thomas

Florian Ragwitz

Larry Pardi

Michael Harmon

Lonnie Koehn

Tim Bray

________________________________________________________

You can also help me make these videos by purchasing via the following Amazon Affiliate links:

Cameras used in this video:

Panasonic GH5 - https://amzn.to/2rEzhh2

Panasonic X920 - https://amzn.to/2wzxxdT

Tools & Shop Products:

"Solidworks 2013 Bible": http://amzn.to/2FObS1D

"Casting Practice – The Ten Rules of Castings" – http://amzn.to/2HF3VfL

"The Backyard Foundry (Workshop Practice Series)" - https://amzn.to/2KdfTip

Calcium Carbonate, 1 pound Capacity: http://amzn.to/2FXGrpb

Salamander A-6 SUPER Clay Graphite Morgan Melting Crucible: http://amzn.to/2pkVAak

Dykem 80300 Steel Blue Layout Fluid, Brush-in-Cap (4oz): http://amzn.to/2HGPaJJ

Hegner Scroll Saw: https://amzn.to/2IhteVW

Blue Matador Abrasive Paper - https://amzn.to/2IAFiBT

Dormer A190202 Jobber Drill Set, 1.0 mm - 6.0 mm x 0.1 mm Size: https://amzn.to/2DR5fdb

Dormer A190203 Jobber Drill Set, 6.0 mm - 10.0 mm x 0.1 mm Size: https://amzn.to/2ITfeTa

Abbreviated Transcript:

02:30 In fact the Roman author and engineer Vitruvius, writing at around the time that the mechanism was lost mentions lathes in a completely offhand manner, expecting the reader to be thoroughly familiar with the idea. As if the technology was so commonplace, that it barely required explaining. As it happens, the Antikythera Mechanism may in fact be the very best evidence available to establish the full extent of that lathe technology, at least as it relates to smaller scale engineering.

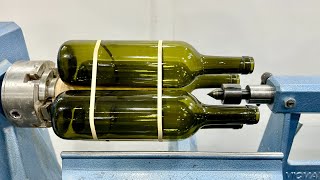

08:37 Next up are what I'm calling the collets, The parts of the tool that'll hold the various drill bits. I cast some long round stock from the same bronze as the flywheel, and then turned it down to an appropriate starting diameter. I then formed the basic collet profile.

11:15 And the same applies to these holes. They're not difficult to form, nor do they need to be terribly precise. They could be made using the lathe tech of the day, or even by using much cruder methods like gouging and then filing. To complete the part, I gave it a light sand, followed by a linseed oil finish.

16:12 In any event, once created, the drill bits themselves can then be used to drill out the collets. Each of the 3 test bits correspond to a critical feature found within the mechanism. One is for a standard bearing hole, one for a standard retaining pin, and the smallest, coming in at just 0.8 of a millimeter, corresponds with the holes used to locate the calendar ring.

16:39 Now there is evidence of the use of soft solder within the mechanism wreckage, and certainly soft solder would be suitable to hold the bits in their collets. But equally plausible, and I think a little more convenient, is resin. I'm using shellac, but any hard resin available at the time would have worked well.

19:58 The changeout of drill bits and flywheels is fast and easy, and the drilling time is comparable to a modern drill. Now as to whether or not this type of tool was used to build the mechanism, well who knows. But I do think its fair to say that its a contender. These test pieces compare well with the holes found throughout the wreckage of the mechanism.

References:

Marcus Vitruvius Pollio: https://en.wikipedia.org/wiki/Vitruvius

De Archetectura by Marcus Vitruvius Pollio:

http://www.perseus.tufts.edu/hopper/t...

TheOlfoundryman on YT: / @olfoundryman8418

Antikythera Fragment #6 - Making A Hand Powered Drill