Published On Oct 16, 2018

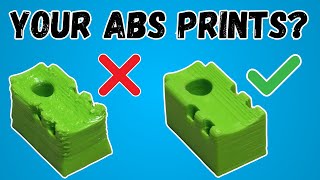

People are often asking in comments how I print ABS on open frame 3D printers. For many prints, producing them in ABS is just a matter of upping the bed and nozzle temps and turning off the cooling fan. Other models, however, are destined to failure.

In this guide, I explore ABS printing successes and failures, and explain why ABS can be so difficult to print using some custom animations.

Summary:

-ABS needs 240+ for nozzle and 100 for bed.

-Fan to be turned off except for bridging, etc.

-Shrinkage occurs on thick/solid objects due to the uneven cooling causing the cooler areas to contract.

-This results in a lifted base and/or splitting between layers.

-The best way to overcome this is to raise ambient temps with an enclosure.

-Otherwise you are limited to printing models with thin or narrow sections.

-ABS is mainly useful for prints that need to withstand higher temperatures.

-ABS can be acetone smoothed!

-ABS releases potentially harmful particles into the air where PLA does not.

-PETG is a good substitute for ABS.

Buy quality and affordable filament from X3D. Buy 3, get 1 free and a free sample pack with every order: www.x3d.com.au

Gearbest affiliate link (help support the channel): https://www.gearbest.com/?lkid=13807527

Take a look around and if you like what you see, please subscribe.

Support me on Patreon: / teachingtech

#3dprinting #abs #explained