Published On Apr 21, 2024

Just about every penny has been pinched on this design. From the undersized resistors to the wiring of the LEDs themselves, which seems to be plain aluminium wire. I couldn't solder to it at all, so had to crimp connections on. That probably means it's relying on the high open circuit voltage to break down oxide formation in the crimped joints when in use. While playing with another string of sockets I had fitted with RGB colour changing LEDs, I had one socket with an intermittent open circuit in it. Either a fractured connection where the wire exits the sleeving, or a bad crimp connection. Very hard to find, as the slightest disturbance of the whole set fixed the problem briefly.

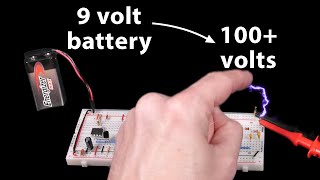

Update - it's NOT using phase angle control. It's pulse width modulating the LEDs on unsmoothed DC and when I shook the lights violently back and forth I was able to see around six distinct dots of light where it was visibly lit in each half wave. Based on the DC humps being at 100Hz and some of the PWM not being illuminated near the zero crossing point, it suggests a possible PWM frequency approaching 1kHz, but modulated at 100Hz. What I thought was a zero crossing point detector for timing is actually just sensing when power is cycled briefly to change mode.

With a longer string of LEDs they will be lit for less time on the unsmoothed DC and shimmer may be more visible.

When I first saw these in huge ornamental lights in the UK I was really surprised to see what appeared to be a long series string of LEDs, clearly running at a fairly high voltage. But literally just stuffed in amongst a mass of coiled aluminium wire forming a plant-like sculpture. It looked good, and it was nice that someone technically inclined could potentially swap in a new LED if desired. But it also meant there were exposed (but slightly recessed) live contacts on each LED's socket.

If an LED was nudged out a bit (easy to do) then there was also the risk of the live leads coming into contact with the metal frame. I'm guessing there may have been some incidents, as they later switched to a low voltage version with the classic heatshrink sleeved LED strings.

The circuitry is very neat though. The tying of pin four of the microcontroller to the positive rail has strong PIC12 vibes to it, as that is the master clear pin when pulled low, and it also doubles as the programming voltage pin, which means it usually needs tied to a supply rail.

The H-bridge for polarity reversal is also a classic design, with the NPN transistor also turning the opposite rails PNP transistor on. In this application the capacitive dropper limits the fault current if things do go wrong.

If you enjoy these videos you can help support the channel with a dollar for coffee, cookies and random gadgets for disassembly at:- https://www.bigclive.com/coffee.htm

This also keeps the channel independent of YouTube's algorithm quirks, allowing it to be a bit more dangerous and naughty.

#ElectronicsCreators