Published On Jun 25, 2023

Making 3D printer filament from cheap pellets 🧵

More info: https://www.DrDFlo.com/Extrusion.html

D-Flo’s Amazon Store: https://www.amazon.com/shop/dr.d-flo

📷 Follow Dr. D-Flo on the Gram: / dr.dflo

Equipment:

EX6 Extruder: https://www.filabot.com/products/fila...

Spooler: https://www.filabot.com/products/fila...

Airpath: https://www.filabot.com/products/fila...

Filameasure: https://www.filabot.com/products/fila...

Description:

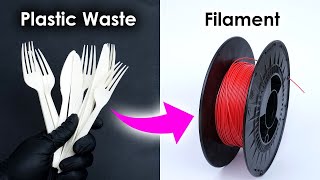

How to make 3D printer filament. This video dives into the fundamentals and technology behind plastic extrusion for 3D printer filament. The workhorse behind this process is the screw extruder, which feeds small plastic pellets into a barrel, where a screw conveys and melts the material. A tight fit between the barrel and screw allows for pressure to build as the plastic melts. This pressure provides the driving force to push the molten resin out of the die (or nozzle) that has a 1.75 mm opening. Of course, this 1.75 mm is the desired filament diameter for most 3D printers, and the melted plastic has no choice but to conform to this profile. The process does not end here as the newly formed filament has to be cooled, measured, and spooled, with each subsequent step requiring its own instrument to carry out.

Each plastic behaves differently during the extrusion process, which provides the opportunity to discuss the molecular structure of polymers (semi-crystalline and amorphous materials). This discussion is not only important in creating the filament but also when printing it. Learn how percent crystallinity affects the tendency of material to warp and their opacity. This video features the extrusion of many different materials, including PLA, ABS, PETG, and HIPS. Also, composite materials, such as carbon fibered reinforced ABS, are also extruded as filament.

Please note: The equipment seen in this video was provided by Filabot, but Dr. D-Flo was not compensated for this video. Dr. D-Flo thoroughly tested all equipment for 1 year prior to making this video.

#Filament #Extrusion #3DPrinting

Table of Contents:

00:00 – Introduction

01:17 – Extruding PLA Filament

09:58 – Die/Nozzle

11:45 – Screw Design

16:47 – Inside the Extruder

18:15 – Barrel Heaters

21:04 – Economics of Filament Extrusion

25:04 – Thermoplastics Structure

27:04 – Purging and Cleaning

27:58 – Extruding ABS Filament

28:58 – Extruding Carbon Fiber ABS Filament

30:02 – Extruding PETG Filament

33:20 – Extruding HIPS Filament