Published On Jan 3, 2021

CONSIDER SUBSCRIBING 🥰

📢Twitter: / breakingtaps

💻Discord: / discord

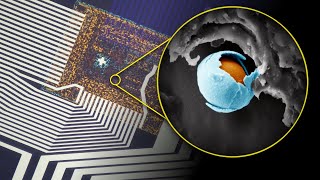

Today we're (micro)-machining glass with a fiber laser. Using a copper sulfate solution, we can etch glass with a pulsed laser like the relatively common Nd:YAG fiber lasers. The CuSO4 solution absorbs laser pulses, vaporizes and forms copper oxide on the surface of the glass. In turn, this oxide absorbs even more of the next laser pulse and generates small explosions of plasma which melt a few microns of glass. The process repeats until you are happy.

This process is known as Laser-Induced Backside Wet Etching, and is used to machine micron-sized features such as microfluidics, microlens arrays, waveguides, microholes and photonic gratings.

Laser is a 50W Nd:YAG fiber laser designed for marking/engraving metal with logos or serial numbers.

Kwon, Kui-Kam, et al. "High aspect ratio channel fabrication with near-infrared laser-induced backside wet etching." Journal of Materials Processing Technology 278 (2020): 116505. https://www.sciencedirect.com/science...

LIBWE: https://scholar.google.com/scholar?q=...

0:00 Intro

2:00 Process explanation

5:57 Why Phosphoric Acid?

7:44 Editorial note: cutting all the way through a coverslip

8:24 Accidental fiberglass

9:06 Highspeed analysis: plasma explosions and more