Published On May 18, 2012

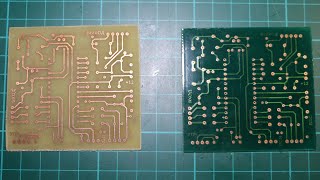

An easily understandable video demonstration of how to make PCBs(Fabricate) at home with available inexpensive materials using toner transfer method.

Requirements for making PCB are Plain copper coated board,Ferric Chloride,PCB hand drill,Hacksaw blade, Iron box, LASER printer(not inkjet) and Glossy paper [photo paper].

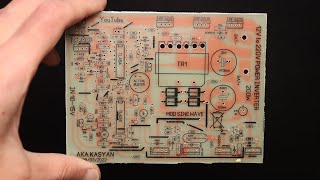

Here Cadsoft Eagle has been used to design board layout,any other CAD tools can also be used.Acetone[nail polish remover] can be used to clean copper surface. Immerse the board for a sufficient time in boiling water for peeling off the paper.While peeling slowly remove the paper from borders don't remove it rapidly since toner might also get removed. If you miss the continuity in the toner mask or if toner gets distorted [path or any small area of design] while peeling off the paper use Permanent marker[like CD maker] to manually draw the path before etching,wash the toner transferred board with plain water and make it dry before drawing with Permanent marker. For fast etching stir the Ferric Chloride solution for every 2 minutes.Air pump agitator[like aquarium air pump] also speeds up the etching process by bubbling through the solution and warm solution can also be used for doing this.

The board made in this video is for object tracking robot using Atmega328p and Xbee Pro.