Published On Premiered Feb 24, 2024

3X Speed and reliability with custom rack and pinion linear actuators for my large format 3D printer.

Files, Parts, and Info: https://www.drdflo.com/LF3DP.html

Large Format Printer Playlist: • Large Format 3D Printer Build Series

D-Flo's Amazon Store: https://www.amazon.com/shop/dr.d-flo

New MDPE10 Extruder: https://massivedimension.com/products...

📷 Follow Dr. D-Flo on the Gram: / dr.dflo

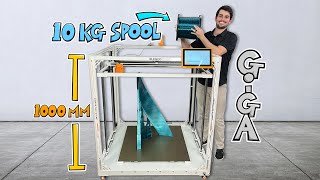

Having printed with hundreds of kilograms of pellets, I've experienced both the incredible potential and the limitations of my DIY Large Format 3D Printer. Further, the acquisition of a new pellet extruder, with a volumetric flow rate five times greater than its predecessor, necessitated immediate upgrades to essential parts of my printing process, including the actuators for improved speed and reliability.

In this video, I detail the process of designing and machining custom carriages to integrate rack and pinion linear motion systems for the X and Y axes (speed!) and ball screw actuators for the Z axis (reliable). I also discuss the workings of the rack and pinion system, its components, and share insights on optimizing this type of linear motion setup for peak performance

Table of Contents:

00:00 - Introduction

00:56 - Relocating Printer

02:00 - Print Speed

06:56 - Z-Axis Ball Screws

13:49 - Ball Screw Actuator Assembly

15:08 - Upgrading the Gantry

16:32 - Rack and Pinion (R&P)

17:09 - R&P Components

21:14 - R&P Tensioning

23:48 - Mounting Gear Racks

24:50 - R&P Testing

28:54 - R&P Actuators Assembly

37:46 - Floating Printhead

40:53 - Machining Carriage Plate

#3DPrinting #LargeFormatPrinting #rackandpinion